Dynomag Hub - Dyno for 2WD/4WD vehicles

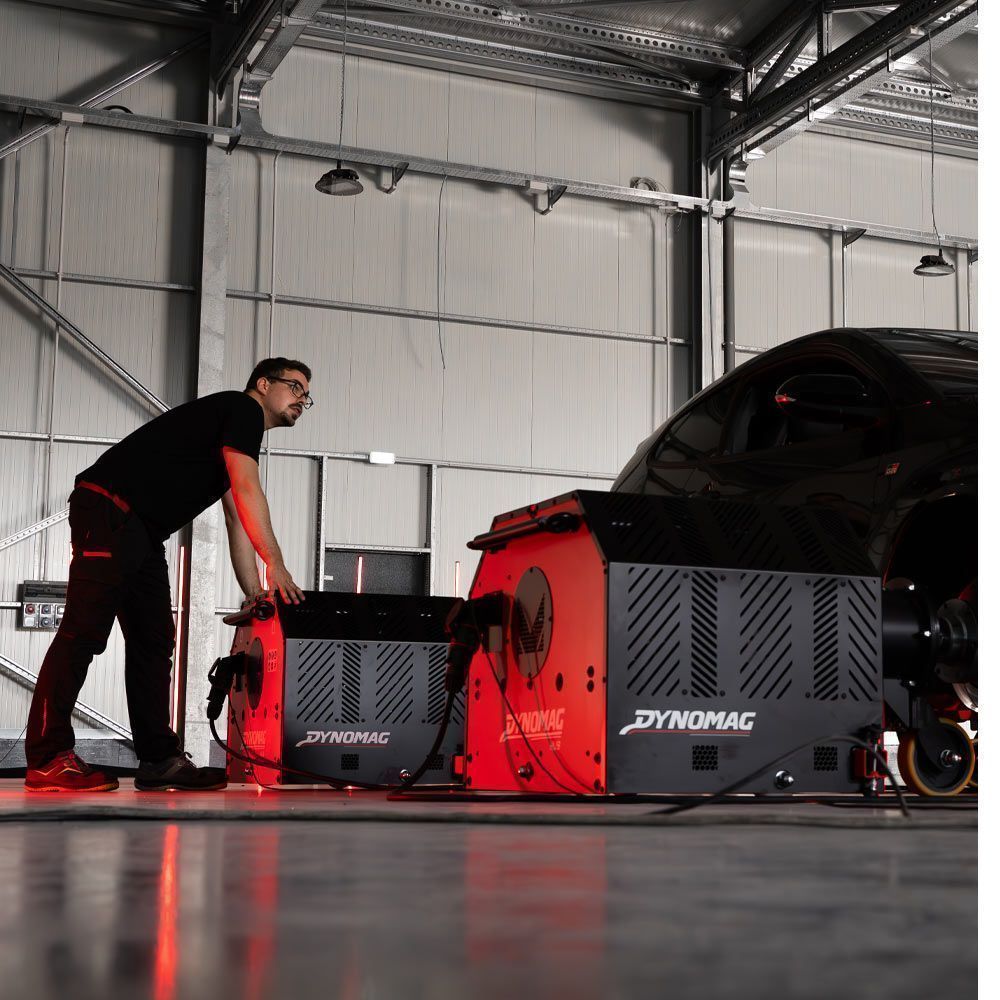

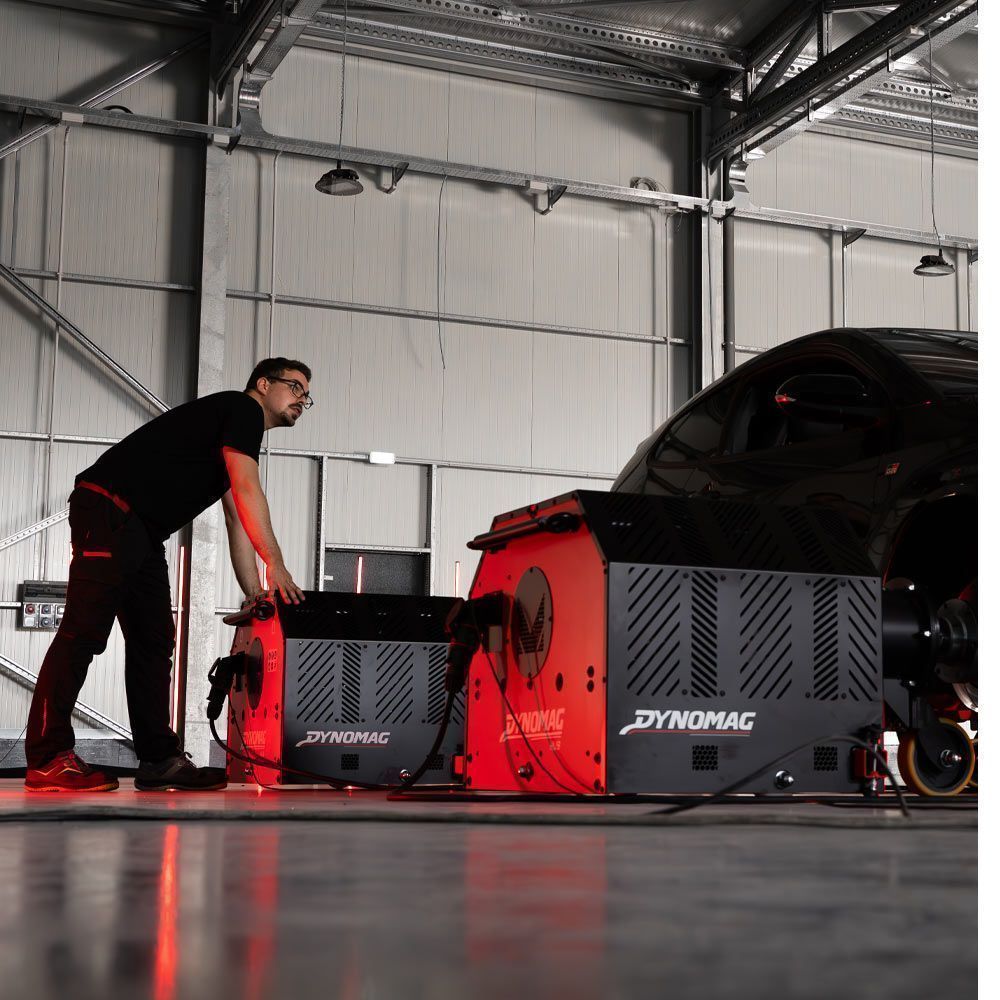

Dynomag Hub is Magicmotorsport's car dyno capable of precise and repeatable tests. Robust and made with a meticulous combination of electronic, technical and structural components, it consists of a control totem and 2 or 4 hubs to be coupled directly to the wheel hub of the vehicle. It doesn't need to be installed permanently, it can actually be stored anywhere after its use.

Main features:

- Small size

- Precise and repeatable measurements

- High levels of safety during tests

- Made in Italy

Description

Mobility and precision

The meticulous combination of electronic, technical and structural components has been perfected to provide mechatronic workshops with a solid and precise hub in any working condition.

The movement system, with a mixture of teflon and rubber wheels, makes it handy and easy to place in any workspace. In addition to that, its jointed axle makes the coupling procedure easier.

Each unit has an high-efficiency eddy current brake equipped with an optimized cooling system to ensure the best thermal and fluid-dynamic conditions.

The absence rollers and wheels increases safety up to the highest levels.

Any parameter under control

Control Totem equipped with a last generation proprietary software, Full HD monitor, high-performance processor and emergency buttons.

Since the very first use to daily operations, mechatronics can have commands, features, and analytics tools at hand.

The totem is ready to support both 2WD and 4WD configurations with the dedicated connection ports.

Two extra Schuko 220v power supply sockets are structurally available.

Modern interface and software

The modern and intuitive software stores the database of tested vehicles, it can start Sweep Test, Constant RPM/Speed/Traction tests, and allows operators to compare several results of different rollings.

Since the very first guided configuration, the proprietary software - constantly updating - coordinates data fluxes coming from electronic tabs of each hub.

Integral passion

Switching from 2WD to 4WD is easy: you just need to connect 2 more hubs to the Dynomag Hub totem.

Differently from chassis dynamometers, where a U-joint or a belt connects the two axles, the hub scalable system is synchronized electronically, not mechanically.

The coupling procedure with the vehicle remains the same, thanks to the wheel hub and centering rings designed specifically for Dynomag Hub.

| Denomination | // | Hub Dynamometer for vehicles |

| Model | // | Dynomag Hub |

| General power supply voltage | [VAC ] | Three-phase: 400 |

| General supply frequency | [Hz] | 50 |

| Level of sound pressure in the workspace | [dB(A)] | < 70 |

| Temperature in the workspace | [°C] | [0 ; + 40] |

| Max. humidity in the workspace | [%] | 85 |

| Possible transmissions | // | Manual, Automatic, CVT (lock mode) |

| Operating voltage | [VAC ] | Three-phase: 400 |

| Max. absorbed power | [A] | [A] |

| Load type | // | Inductive |

| Power output | [VAC ] | Three-phase: 5 x 400 Single-phase: 4 x 240 |

| Max. output power | [A] | Individual three-phase (5 outputs): 20 / Total single-phase: 16 |

| Safety systems | // |

Differential circuit breaker: Three-phase: 20 A curve C, IΔN = 0.03A Type A individual for each output Single-phase: 16 A curve C, IΔN = 0.03A Type AC overall |

| Totem weight | [Kg] | 180 |

| Max. Totem size | [mm] | 1720 x 950 x 920 |

| Single-hub electric current | [A] | 16 |

| Max. hub rotation | [rotation/min] | 3000 |

| Max. braking torque | [Nm] | 1600 |

| Max. Camber/Toe angles | [°] | -+ 8 |

| Hub Weight | [Kg] | 500 |

| Max. Hub size | [mm] | 1300 x 950 x 750 |

| Wheels | // | Allow an easy tilting of the hub and facilitate its repositioning |

| Electric current | [A] | 32 |

| Max. braking torque | [Nm] | 3200 |

| Max. braking power | [CV/rpm] | 800 / 2000 of the axle |

| Max. axle load | [Kg] | 3000 |

| Electric current | [A] | 64 |

| Max. braking torque | [Nm] | 6400 |

| Max. braking power | [CV/rpm] | 1600 / 2000 of the axle |

| Max. axle load | [Kg] | 3000 |

How It Works

Package Content

| Sku Code | Description | |

| DNH02.001 | Dynomag Right Hub | |

| DNH02.002 | Dynomag Left Hub | |

| DNH03.001 | Dynomag Hub Assembled CAN cable | |

| DNH03.002 | Dynomag Hub Three-phase power cable | |

| DNH01.005 | Dynomag Hub Centering Ring Kit | |

| DNH02.000 | Dynomag Hub Totem |